Bovone

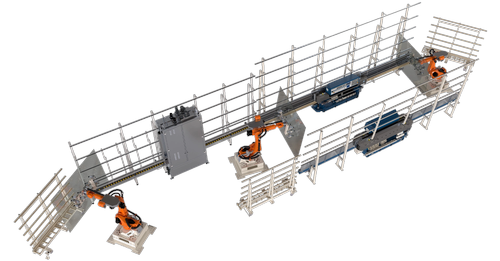

Robot Line

Bovone has always been synonymous with excellence and quality that lasts over time: maintaining this reputation is the main goal of all the workers of the company.

Bovone s.r.l. is today a reality present all over the world where it operates through qualified agents who often also provide technical assistance and ensure a spare parts warehouse. Furthermore, the qualified Bovone technicians are always ready to visit the customer.

a world renowned reputation for highest quality machinery

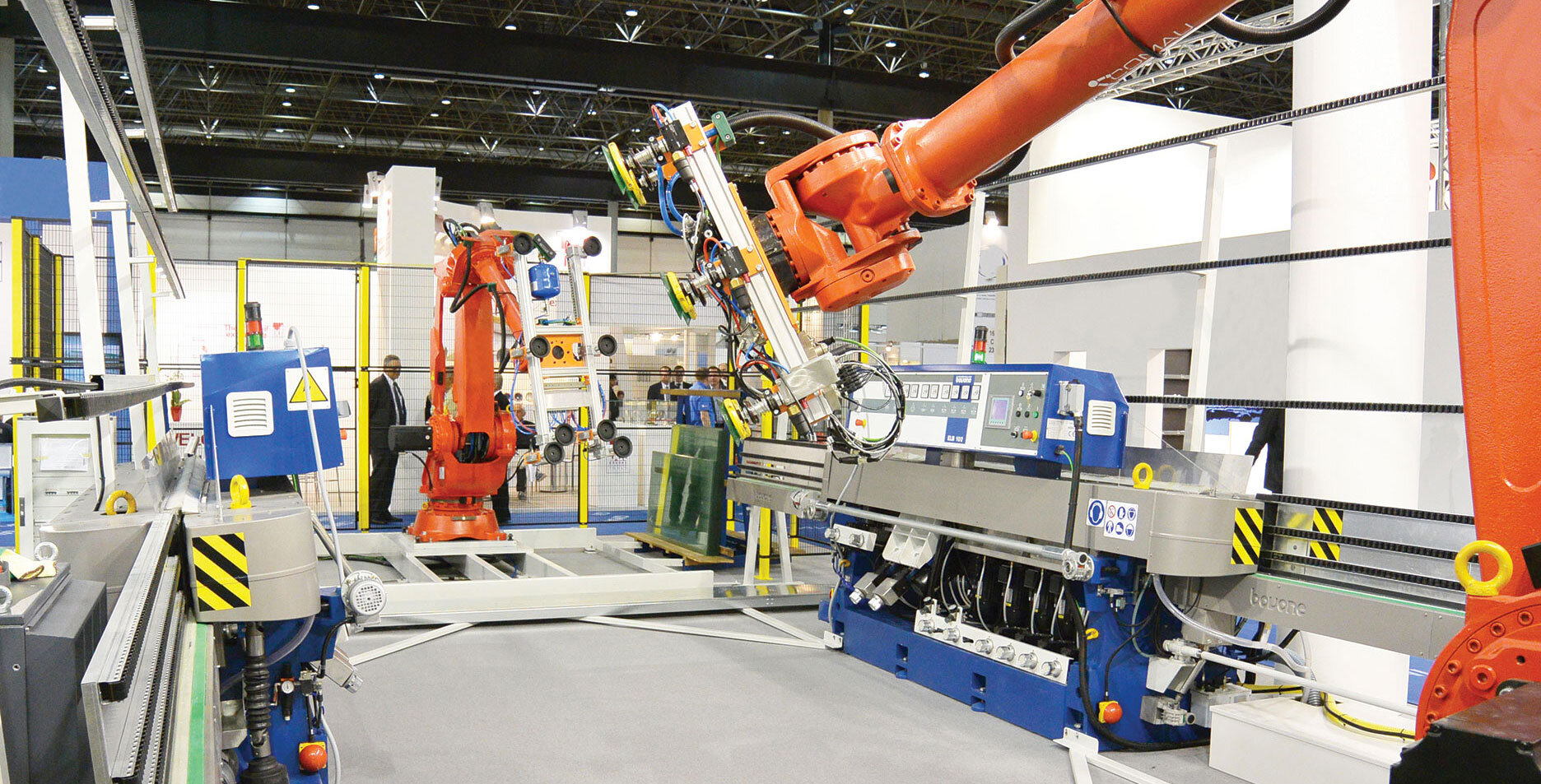

Bovone is leading the way in volume glass processing. As an alternative to the conventional glass double edging line, the solution from Bovone is to place two straight line edgers facing each other with a robot placed at each end of the in-feed conveyors to automatically load, turn and unload. Mixed batches of work are loaded onto a trolley, identified with the use of a bar code system. The operator places the loaded trolley in the working zone, exits the area, and then the line controls everything. All the adjustments for grinding, speed, thickness, size and even wheel wear is taken care of by the Bovone automatic system.

increased production

The robotic integration allows a considerable increase in productivity, with reduced costs and greater safety for the operator in the handling of large glass sheets.

Efficiency

The development of the glass grippers designed with reduced weight and size enhance performance by saving time and energy during the processing cycle (up to 25% less than similar equipment)

express toughening

Back in 2016, Stone & Glass Group installed the first Bovone Robot System into the UK market, at Express Toughening, which is still used in production every day, which allows them to grow, year on year.