Systron

handling solutions

Systron

Systron glass processing solutions stand for tremendous flexibility on smallest installation space to achieve optimal growth with little infrastructural and personnel investment. Low operating costs, best quality and consistently high output result in a fast return of investment.

Robot Integration

Industrial robots from Kuka, coupled with a Systron solution, increase the degree of automation of your production significantly. We integrate them seamlessly into our concept and control them with absolute precision.

Highlights:

- Reliability, constant and stable equipment loading and unloading

- Security, less risk for workers handling glass

- Innovative and space-saving

Shuttle

The “systron SHUTTLE” is an automatic glass transport robot shuttle which transports glass panes vertically between processing stations. The rail system is designed for very high speeds and accelerations.

Highlights:

- Optimized cycle time, glass transport is carried out during the shuttle movement

- Expandable, through standardized rail system

- Low maintenance, thanks to automatic lubrication system

Turn Shuttle

The “systron TURN SHUTTLE” is an automatic glass transport shuttle with turning function. Specially designed to feed processing lines.

Highlights:

- Cycle time optimized, glass transport is carried out during the shuttle and rotary movement

- Flexibility, ideal for applications with limited space

- Expandable, through standardized rail system

- Low maintenance, thanks to automatic lubrication system

Storage

The “systron TURN SHUTTLE” is an automatic glass transport shuttle with turning function. Specially designed to feed processing lines.

Highlights:

- Cycle time optimized, glass transport is carried out during the shuttle and rotary movement

- Flexibility, ideal for applications with limited space

- Expandable, through standardized rail system

- Low maintenance, thanks to automatic lubrication system

Tilting Table

The systron TILTING TABLE serves as an interface between the horizontal and vertical transport of glass panes.

Depending on the requirements, the “systron TILTING TABELE” carries one or more panes of glass.

Horizontal – Vertical | Vertical – Horizontal

Highlights:

- Low maintenance due to a solid construction

- Dynamic and precise, thanks to integrated servo technology

Rail Tilting Table

In addition to the connectivity of horizontal and vertical glass transport routes, the “systron RAIL TILTING TABLE” can also be used as a cross transport to take advantage of local conditions or to give new concepts maximum performance

Highlights:

- Flexible in the movement

- Dynamic, exact and repeatable thanks to integrated servo technology

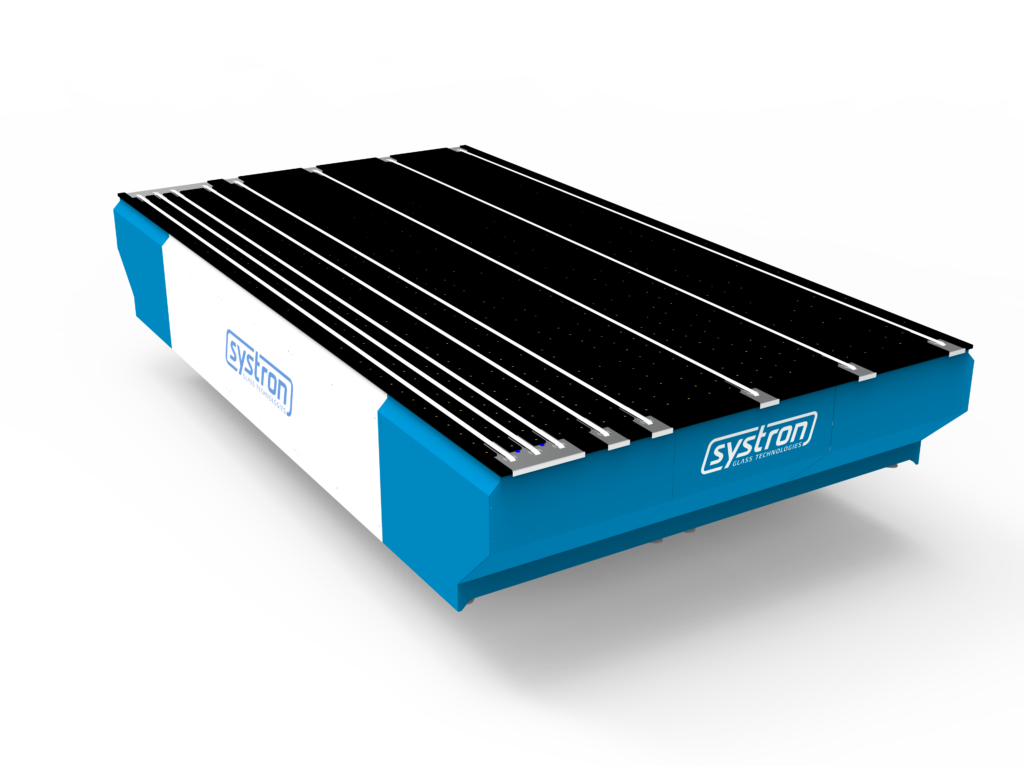

Air Cushion Table

In addition to the connectivity of horizontal and vertical glass transport routes, the “systron RAIL TILTING TABLE” can also be used as a cross transport to take advantage of local conditions or to give new concepts maximum performance

Highlights:

- Flexible in the movement

- Dynamic, exact and repeatable thanks to integrated servo technology

Transport Passage

The “systron PASSAGE” makes it possible to pass through transport routes.

Highlights:

- Flexibility through modular design

- Easy and fast installation

Inspection

The “systron INSPECTION” is a control track for optical inspection of the glass.

The structure with the indirect LED lighting is fatigue-free for the eyes and makes disturbances in the glass surface appear particularly clearly visible.

Highlights:

- Indirect illumination by means of LED

- Space-saving modular design

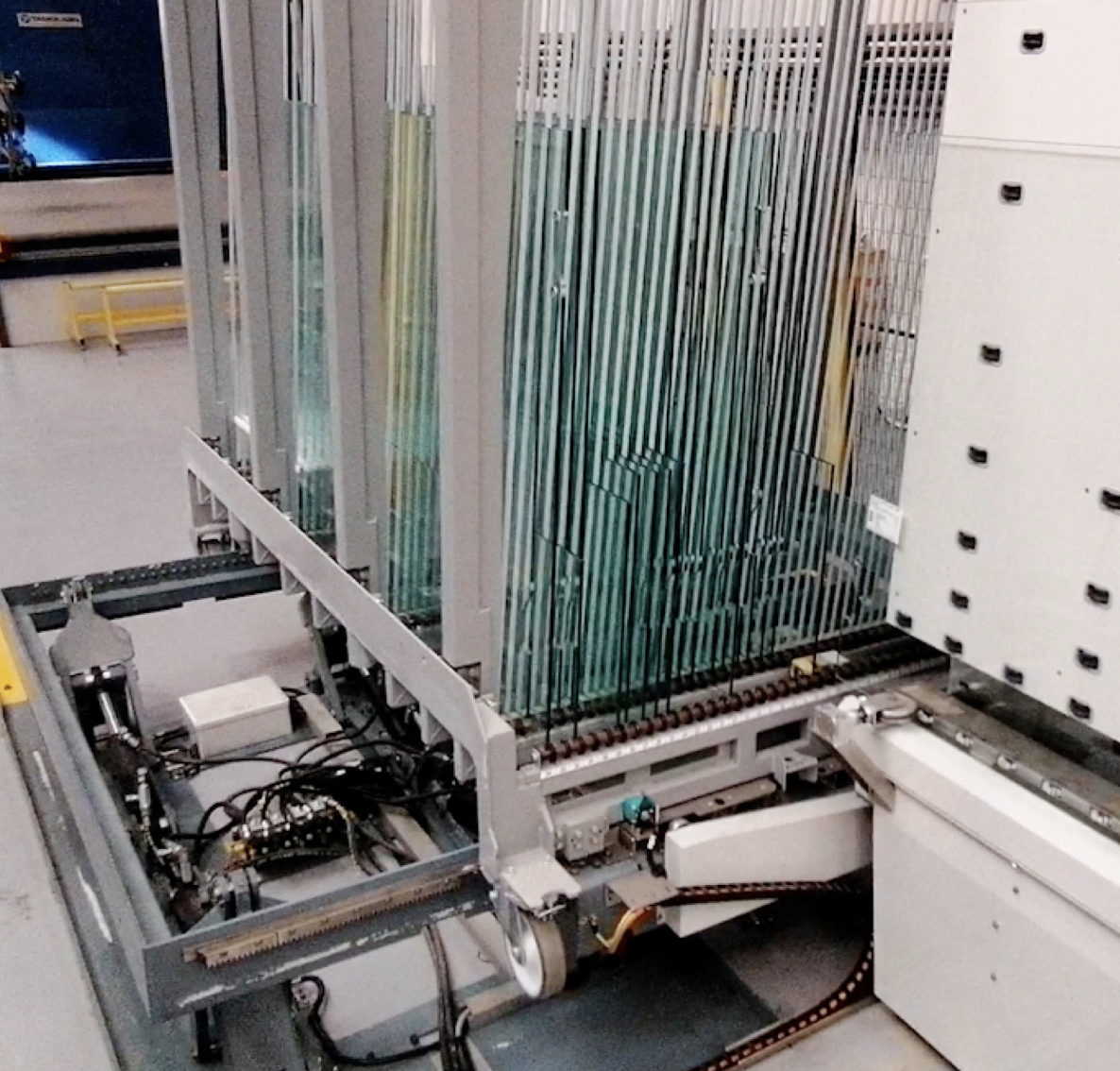

Automated Storage Solution

The automated glass storage solution is the ideal option for customers who use racks from any manufacturer as an internal means of transporting glasses.

This solution offers the machine operator an optimal time management. The load of the inline glass storage is processed fully automatically and then buffered in the storage on the outlet side. Due to a significant reduction in work steps, a second machine can be operated in face-to-face mode.

INCREASED EFFICIENCY BY AUTOMATION:

Optimal operating process without downtime due to handling, breaks or shift changes

Up to 4 hours of production without a machine operator

Capacity increase by ~ 20%

Increase in quality by minimizing handling

All systron machines can be supplied and retrofitted with the automated storage solution.

HARP RACK SOLUTION

The automated harp rack solution is the ideal option for customers who use harp racks as an internal means of transporting glasses.

A harp rack is docked to the systron machine on the inlet and outlet side while the glass is processed fully automatically. The tasks of the machine operator are thus reduced to harp rack handling, tool management and quality control. So it’s possible to operate a second machine in face-to-face mode.

INCREASED EFFICIENCY BY AUTOMATION:

Optimal operating process without downtime due to handling, breaks or shift changes

Up to 5 hours of production without a machine operator

Capacity increase by 25%

Increase in quality by minimizing handling

All systron machines can be supplied and retrofitted with the automated harp rack solution.