Systron

prohd vertical cnc

for multiple shifts

Systron

Systron glass processing solutions stand for tremendous flexibility on smallest installation space to achieve optimal growth with little infrastructural and personnel investment. Low operating costs, best quality and consistently high output result in a fast return of investment.

advantages

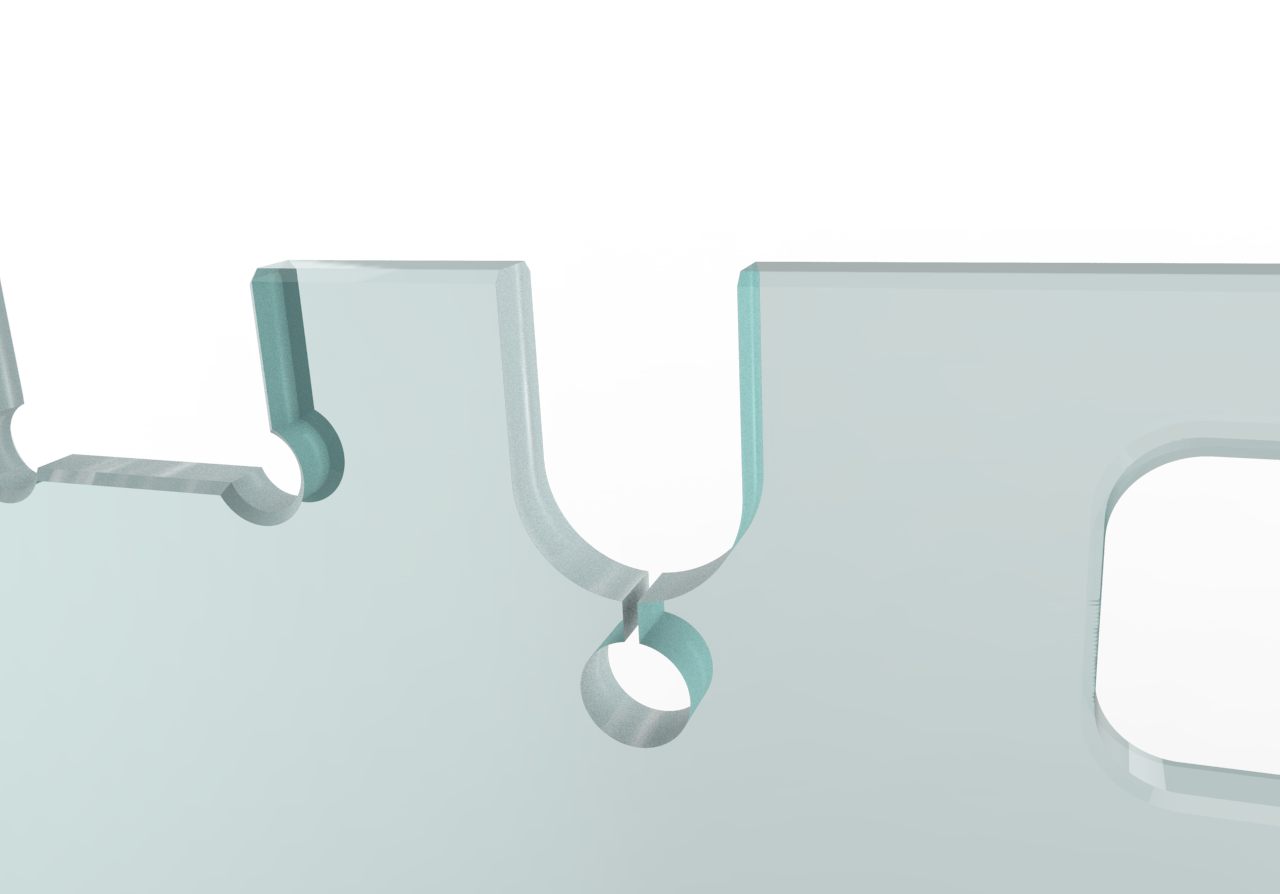

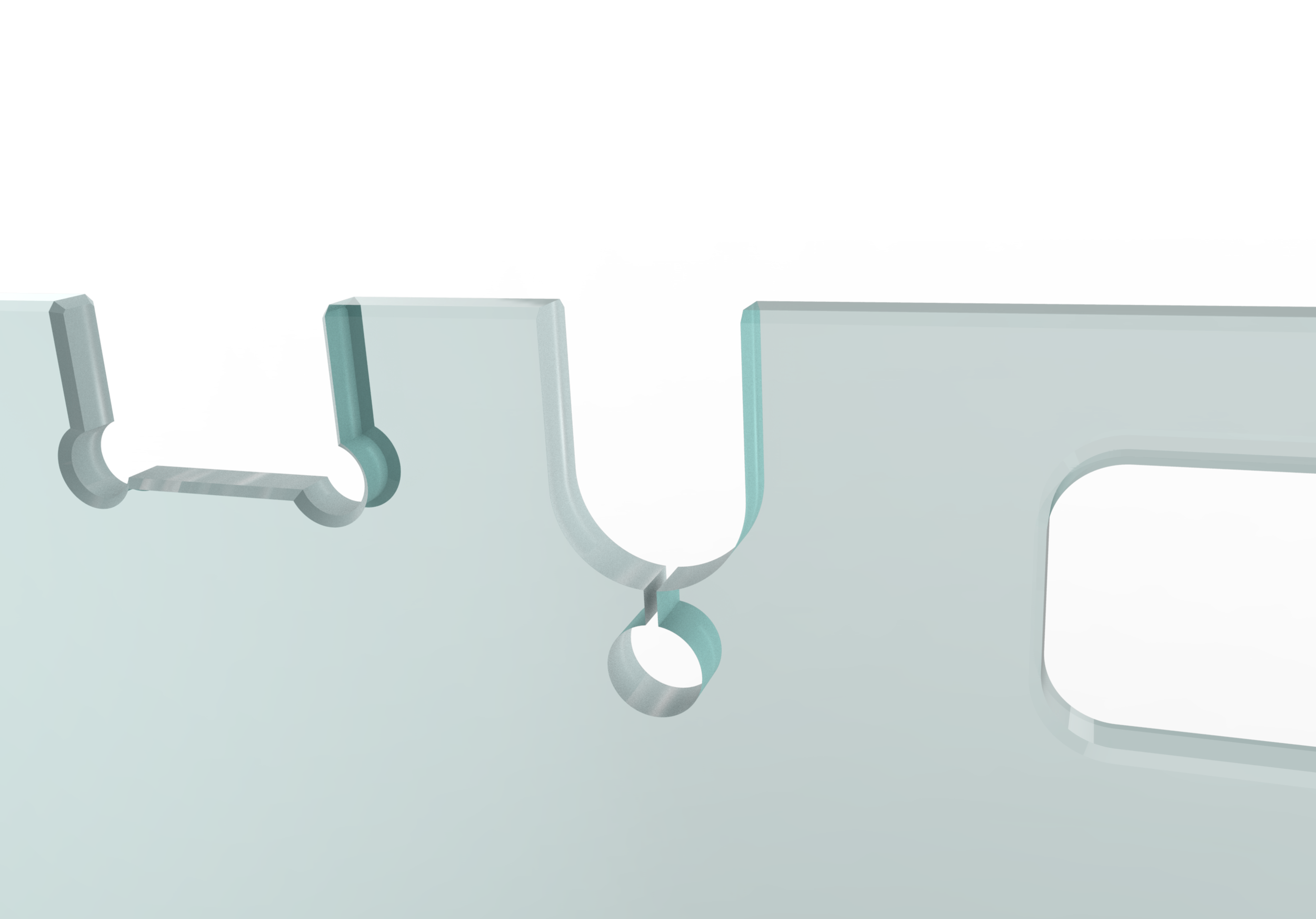

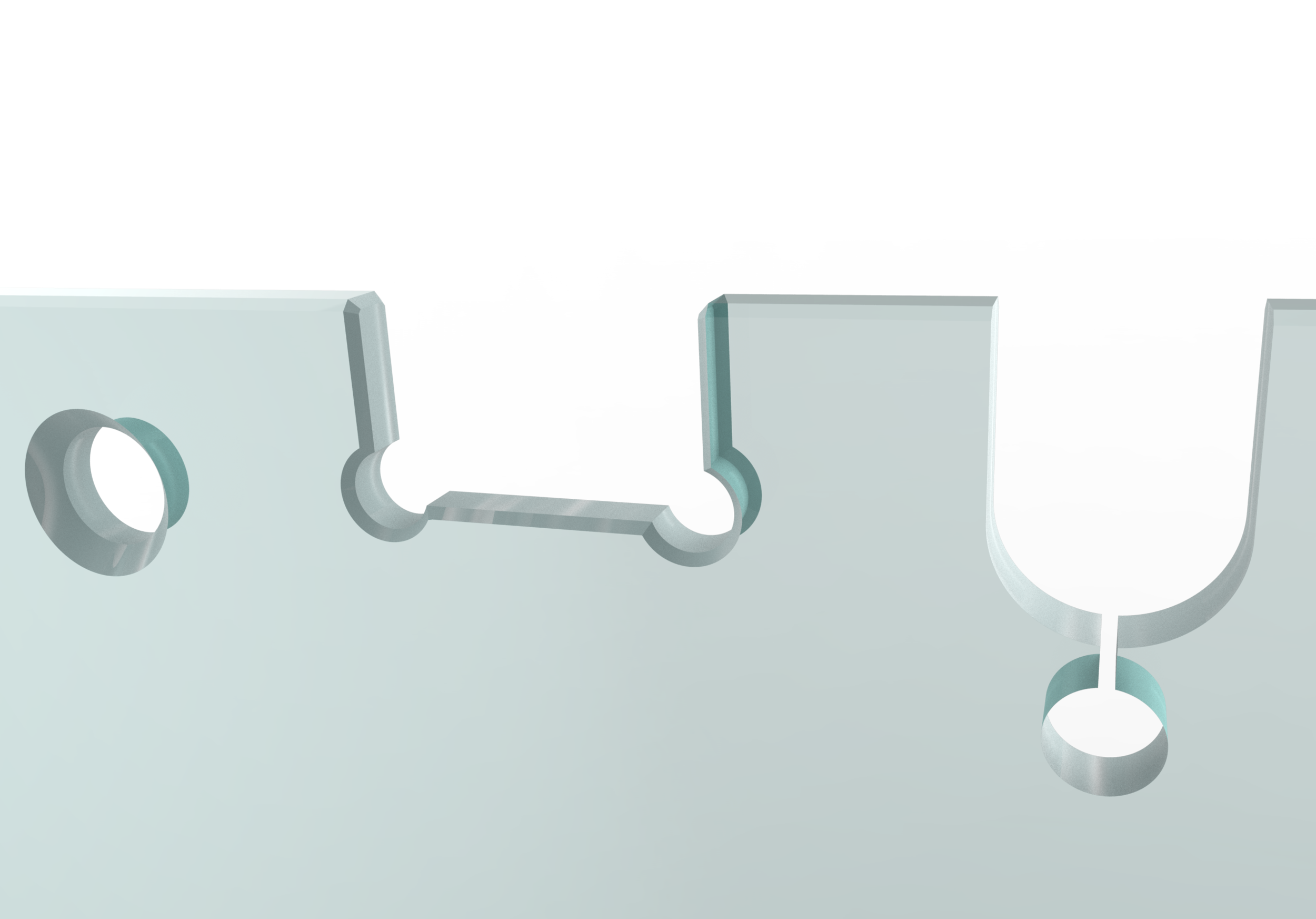

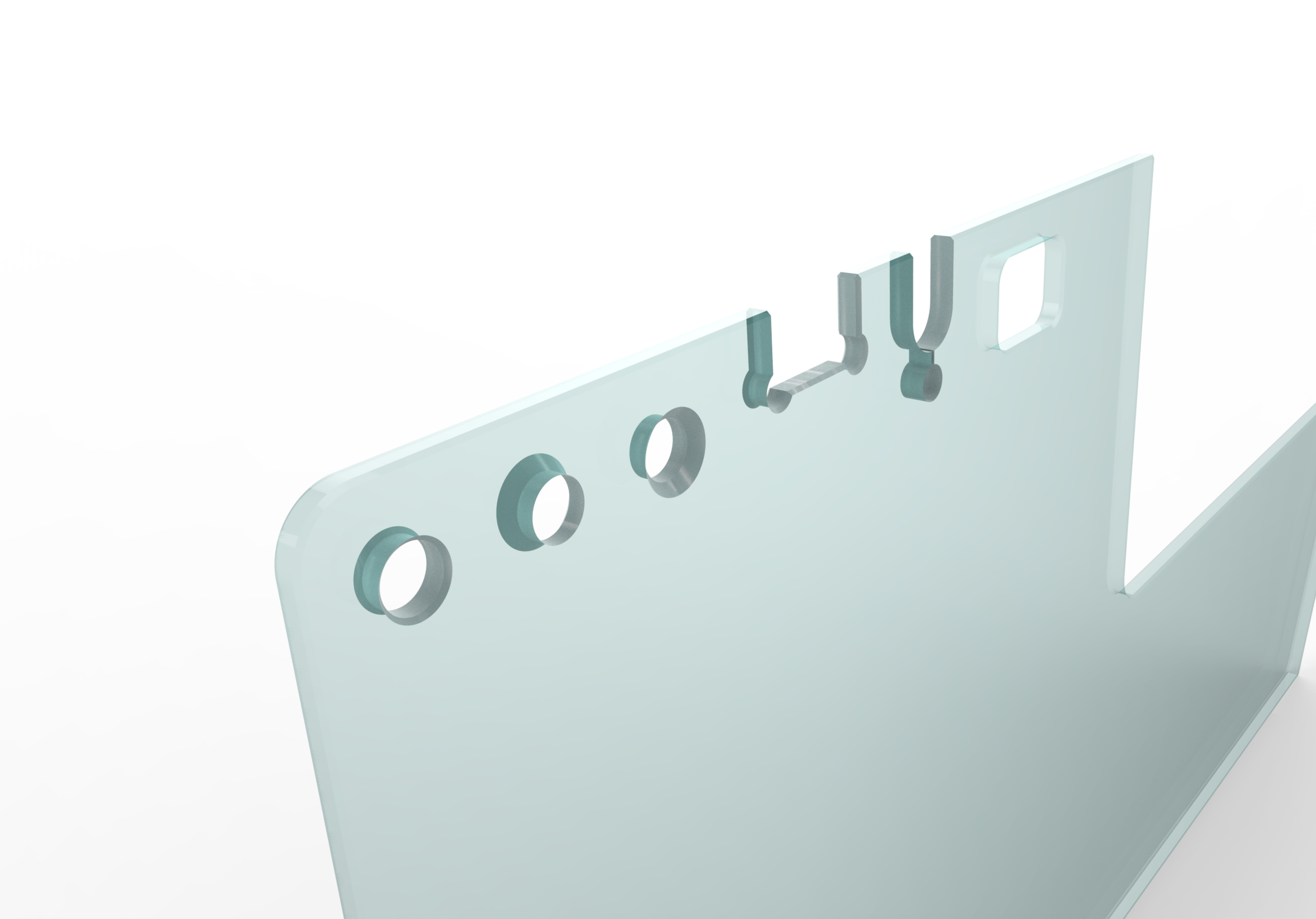

Glass Grinding of inner and outer contours

Glass Polishing of inner and outer contours

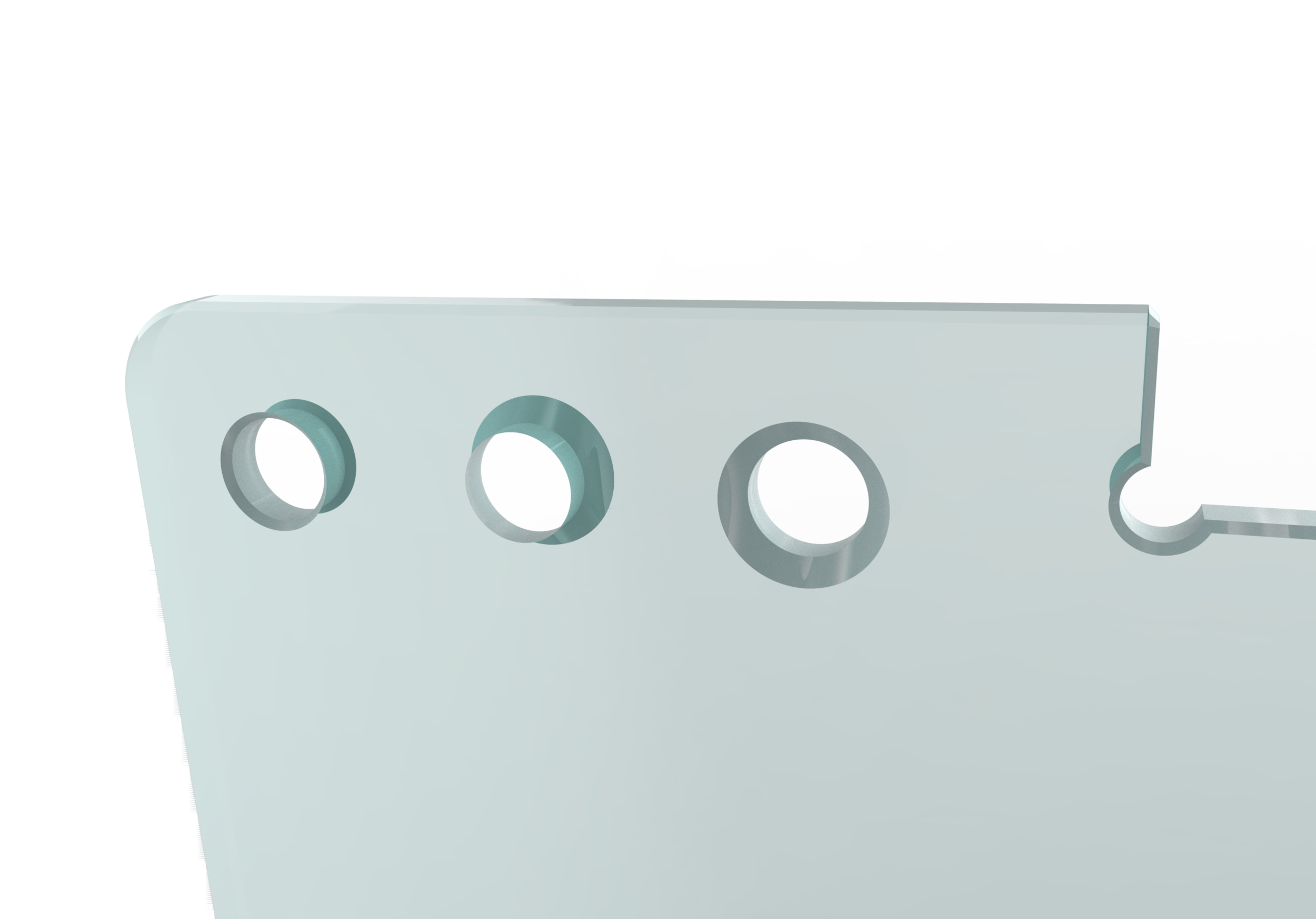

Glass Holes and cutouts by means of water jet technology

Glass Deep counter sink - both sides by means of the helix method

Tool Changer

The possibilities of systron proHD include the following features, clamping once for all interior and exterior machining, minimal machining tolerances, no machining restrictions on contours and special glass shapes, no set-up times between different glass thicknesses and types & vibration-free construction allows the highest processing quality also at oblique edges.

highlights

Up to 4000 bar strong water jet

Chain magazine for 50 tool holders – up to 100 tools

Vibration-free construction

Clamping beam equiped with suction cups

Automatic positioning of the glass sheets, also for special shapes

Low maintenance costs of the high pressure unit by new / patented systems

No mechanical contact at machining coated glass surfaces

Intuitive graphical machine interface enables easy operation of the system

Constant polishing quality by precisely controlled polishing pressure

Vibration-free machining prevents chipping

Arris parallelism guaranteed by patentend waterpillow guidance

High pressure tool cooling over the entire tool circumference