R&R

Spacer bar

Rottler und Rüdiger

In keeping the motto "Upgrading your glass", we have been your competent partner for the insulating glass industry for four decades now.

We offer production systems for spacer bar and Georgian bar processing, are a system partner for Georgian bars and a reliable supplier of high-quality consumables for all aspects of flat glass processing.

Roweldo

Low PSI Processing

Swisspacer, Multitec, Precision - equipped for modern low psi profiles.

With our tried-and-tested Roweldo-Romillo combination, one person can achieve cycle times of less than 30 seconds. Suitable for processing all standard low psi profiles such as Swisspacer, Multitec, Precision or comparable products.

Romillo

Frame parts are milled to 45°

Automatic insertion of the corner brackets

Longitudinal welding of the profiles for endless connection

Compatible with 25-compartments magazine PWM 20 XL

Cycle times of less than 30 seconds

Minimal waste due to optimum residual length management

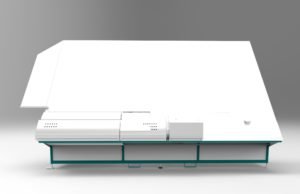

Roweldo S - the 4-head welding system

Automatic welding of the corners one after the other

Manual positioning for the welding process

Clean corners, therfore a proper butyl surface and minimal thickening

Interior view is identical to inserted corners without any deformities

High frame and dimensional stability

Automatic positioning of the welding head through online connectivity

Cycle times of less than 50 seconds

Bendit with Low Psi Option

Integration of Multitec, Precision, Swisspacer processin

Individual magazine configurations between 10 and 25 compartments

Universal bending tools for almost all hybrid profiles

Tight corner radii

Rolling technique to support plastic deformation

Counter support bending with profile-specific tools for almost any profile

Modular machine design for perfect customisation

Large one-piece frames

Integrated radius bending

Bendit XS

We also have the right technology in our range for smaller productions. With our Bendit XS manual bending machine, you can manually shape your spacer frames.

Radius Bending ABH

Our manual radius bending machine ABH gives your spacer any desired curve - leaving no (customer) wishes unfulfilled. And to save you time and money, you can easily bend profiles between 12 and 20mm with just one set of rollers.

Profile Change Magazine PWM-XL

To meet the demand for more and more different spacer types and colours in the manufacturing process, we have developed individually scalable magazine solutions for our spacerframe benders and welding machines. These allow our customers efficient and uninterrupted production even with a high variance of spacer colours and dimensions.

DesiQuant

a hole is drilled into the back of the profile on the corner in two frame sides

automatically adjusts to the profile width; spacer sizes 6-32 mm

filling is controlled by weight measurement

automatic closure of the holes with butyl

Single bar filling

Container volume 50 litres

optionally available with a supplementary high suction device for a 200 litre container

DesIQuant - OFFLINE; conversion and display of the filling weight in profile lengths

DesIQuant - ONLINE; precise filling according to previously calculated values

Recording and storage of filling data in ONLINE mode

SAE

Double saw for plastic/aluminium and stainless steel profiles

Two separate saw drives

Automatic clamping directly above the cut

Two-hand operation

Variable blade speed

Adjustable saw hub

Flexible sawing solution for every need

Special models available with only one saw each

LAS-A

Motorised stop

Online connection or manual input

Professional order management

Import of bending data possible

Connection of ink jet printers for inline marking possible.

Offline model calculation possibl

Transport

Whether standing or hanging. We move your spacer frames, Georgian bars and prepared components securely and efficiently within your production. This not only saves time and money, but also spares the nerves of your employees.